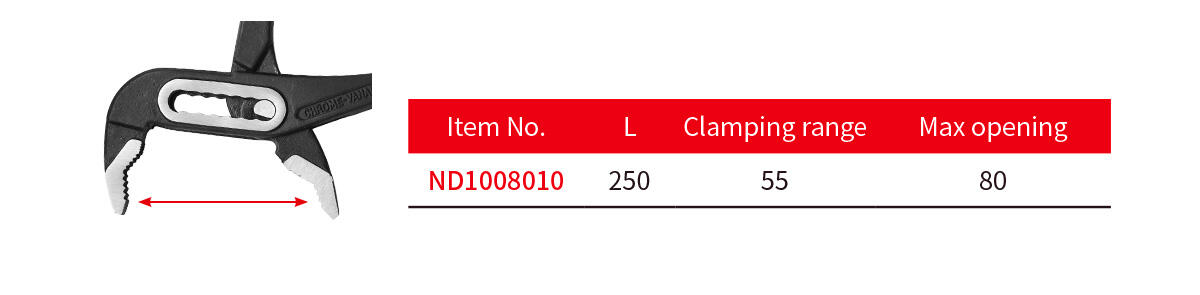

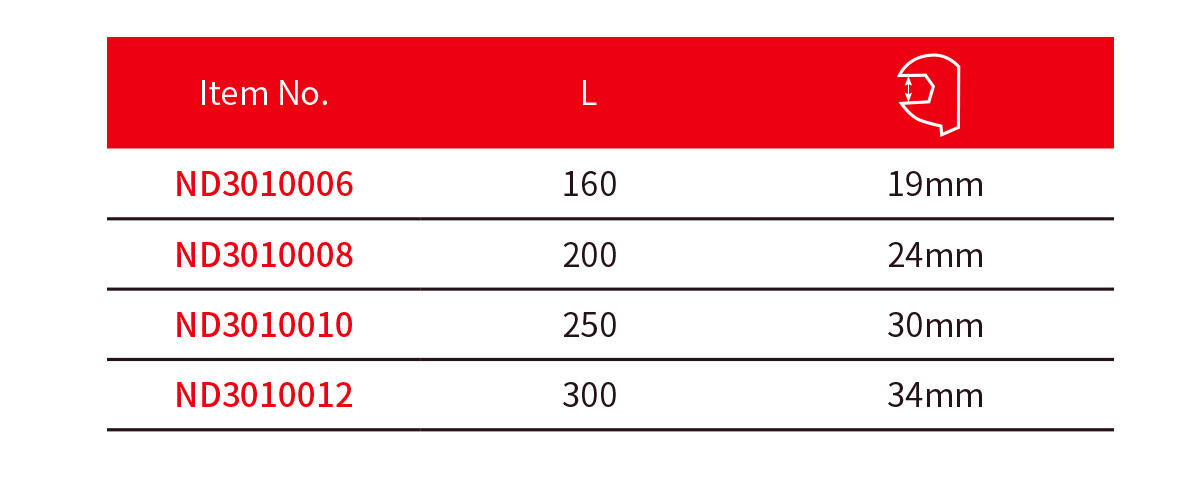

snip straight and bent heavy duty

The snip straight and bent heavy duty is a robust and versatile tool designed for high-intensity cutting applications. Engineered with precision, its main functions include cutting through tough materials such as metal rods, cables, and wires with ease. Technological features of this tool include a high-quality steel construction, providing durability and extended life, even in the harshest conditions. The handles are ergonomically designed for a comfortable grip, reducing user fatigue during prolonged use. Additionally, the cutting edges are induction-hardened to stay sharp for longer periods. This tool finds extensive applications in various industries, including electrical, plumbing, and automotive, where heavy-duty cutting tasks are a daily requirement.