Key Features of High-Quality AVIATION Snips

Blade Material and Hardness (56-62 HRC)

The blade material is key to the cutting power and lifespan of aviation snips. Two common materials are:

⢠Cr-V (Chromium-Vanadium Steel): Strong and durable, suitable for general-purpose cutting.

⢠Cr-Mo (Chromium-Molybdenum Steel): Tougher and more wear-resistantâbetter for frequent.

Many blades also feature chrome-plated or anti-rust coatings to reduce corrosion and extend tool life.

Hardness Matters: 56â62 HRC

Blade hardness, measured in HRC (Rockwell Hardness Scale), typically ranges from 56 to 62 HRC. A higher number means:

⢠Better edge retention

⢠Cleaner, more precise cuts

⢠Longer blade life

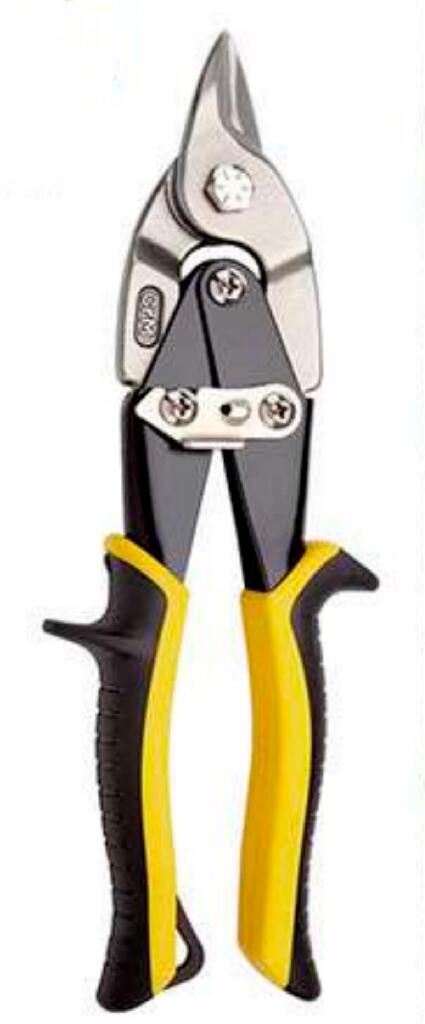

Ergonomic Handle Design for Fatigue Reduction

Aviation snips with ergonomic handles are designed to reduce hand fatigue and improve comfort during long periods of use. A key feature is the use of TPR (Thermoplastic Rubber) material, which offers a soft, non-slip grip and excellent handling.

What makes Aviation Snips is that itâs also an environmentally friendly properties.

Benefits of TPR Ergonomic Handles:

⢠Reduces hand strain and fatigue

⢠Enhances grip and cutting control

⢠Promotes longer, safer use

⢠Adds eco-friendly value to the tool design

By combining comfort and sustainability, TPR handles make aviation snips both user- and environment-friendly.

Cutting Capacity (Gauge Compatibility)

The cutting capacity of aviation snips refers to two key factors:

1. The maximum thickness of material they can cut

2. The cutting lifespan, or how many times they can cut before wearing out

TIANXIN Aviation Snips Cutting Performance

⢠Cuts 1.5mm cold-rolled steel effortlessly

⢠Handles 0.9mm stainless steel cleanly

⢠Lab-tested to cut white iron sheet over 30,000 times

This means TIANXIN snips not only handle thicker, tougher materials, but also offer long-lasting durability, making them ideal for both industrial and daily use.

Compound Leverage Mechanisms

The compound leverage system found in aviation snips really boosts their cutting power, so users don't have to strain as much when working with different types of metal. Basically, these snips multiply the force someone applies, then channel that extra strength through strategic pivot points which makes everything cut smoother and faster. Some tests actually indicate that this kind of mechanism can boost cutting performance by around 60 percent compared to regular pliers. That means less muscle burnout during long jobs, which matters a lot for anyone spending hours on metalwork projects. For instance, automotive technicians appreciate how these specialized snips handle thick sheet metal without the usual hand cramping that comes with standard cutting tools.

Types of Aviation Snips for Specific Applications

Aviation Snips: Curved and Straight Cuts

Aviation snips cut through materials with precision where regular tin snips just won't do. Their short blades combined with solid handles make it possible to tackle those tricky curved cuts as well as straightforward ones. Sheet metal workers swear by them when working on aircraft parts or building HVAC systems because they can bend around tight corners without breaking stride. Most pros know that picking the right snip matters a lot depending on what kind of job lies ahead. Left-handed, right-handed, or straight blades each serve different purposes in real world situations. From repairing airplane fuselages to putting up ductwork in commercial buildings, these specialized tools deliver consistent results time after time. Getting familiar with how different models perform under various conditions helps technicians pick the most suitable option for their particular needs.

Straight-Cut Snips for Long Seams

Straight cut snips stand out as must have equipment when working with metal along straight lines and seams. These tools come with longer blades that let workers handle extended cutting jobs efficiently, something that matters a lot in fields such as heating ventilation air conditioning work and roof installation projects. Workers often reach for straight snips when dealing with things like ductwork seams or sheet metal panels on roofs, since getting those cuts right matters both aesthetically and functionally. For best results, most experienced technicians recommend starting slow and steady while applying even pressure all the way through the material. This approach helps avoid those frustrating jagged edges that nobody wants to deal with later. Because they can deliver those clean, straight cuts over distance, straight cut snips remain go to tools across construction sites and manufacturing facilities everywhere.

Offset Snips for Tight Spaces

Offset snips were made specifically for those really tight spots where regular tools just won't fit. The angle on these snips lets workers keep their hands clear of whatever they're cutting, so there's no fumbling around or getting blocked by the material itself. This makes all the difference when working in places like HVAC ducts or deep inside industrial equipment where space is at a premium. Most people who have used them report how much easier jobs become once they switch to offset snips. They can get into corners and crevices that standard snips simply can't reach without sacrificing the quality of the cut. Mechanics and fabricators across various industries rely on this tool because it actually gets the job done in situations where other tools fall short.

Bulldog Snips for Thick Materials

Bulldog snips have solid build quality which makes them good for tackling thicker stuff. These snips come with shorter blades but pack a real punch when gripping materials. They work great on things like heavy gauge sheet metal and those metal reinforcements found in construction projects. Most metalworkers reach for bulldog snips when they need to get through tough materials because they can make clean cuts without wearing down the tool itself. Want these snips to last longer? Keep them well maintained. Sharpen those blades regularly and don't forget to oil the pivot points so everything moves smoothly. Anyone who works with metal knows how handy bulldog snips are when cutting through thick stock. Just ask any construction worker dealing with steel framing or HVAC installations.

Top Considerations for Precision Cutting

Blade Sharpness and Serration Patterns

How sharp a blade is makes all the difference when it comes to getting accurate cuts and making work easier overall. When blades are sharp, they cut through materials much faster without needing as much force, which saves time and energy during projects. The choice between serrated and straight blades really boils down to what needs to be cut. Serrated edges tend to bite better into things like wet leather or tough fibers that might otherwise slip around during cutting operations. Straight edged blades generally give cleaner results especially when working with thin metals where precision matters most. Keeping blades sharp remains important throughout their lifespan. Most experienced workers know that consistent maintenance including proper storage conditions and timely resharpening can extend tool life considerably while maintaining optimal cutting capabilities across different applications.

Left/Right-Cut Versatility

Tools that can cut in both directions are really important when dealing with all sorts of different jobs around the shop. The ability to switch between left and right cuts makes things run much smoother for workers who need to make precise cuts no matter which way the material is oriented. This kind of feature comes in handy especially on jobsites where conditions change constantly and workers need to adjust quickly. Take HVAC technicians for instance they often find themselves working in tight spaces where traditional snips just won't do. Metal roof installers also rely heavily on these dual cutting tools because roofing materials come in so many different configurations. Most experienced tradespeople will tell anyone who'll listen how much time and frustration these versatile snips save them day after day on real world projects.

Maintenance and Safety Best Practices

Cleaning Metal Shavings and Debris

Keeping aviation snips in good shape matters a lot if they're going to last and work well. Regular cleaning of metal bits and junk stuck on them makes all the difference. Left unchecked, those tiny metal scraps collect around the blades and where the tool pivots, which slowly makes cuts less effective and can actually damage the tool itself over time. A decent cleaning routine means grabbing either a stiff brush or blowing out debris with compressed air. Don't forget protection though! Gloves and safety glasses should be part of every cleaning session because those little metal fragments are razor sharp and will definitely cause problems if not handled right. Shop floor data shows that tools maintained properly just don't break down as often, and workers get hurt way less frequently too. Simple maintenance really pays off in both safety and money saved long term.

Lubrication for Smooth Operation

Keeping aviation snips properly lubricated is really important for them to work smoothly over time. When we talk about regular maintenance, what happens is that lubricant cuts down on the friction between all those moving components inside the tool. This helps extend how long the snips last before needing replacement while also making sure they perform better when cutting materials. Most people find that putting some oil on their snips once a week works pretty well, though if someone uses theirs every day at work, maybe more frequent application makes sense. For best results, light machine oil or even multipurpose grease tends to do the trick for keeping both blades sharp and pivots functioning correctly. If folks skip this step altogether, they'll notice their tools start wearing down much quicker than normal. Worse still, the cuts won't be as accurate anymore because everything gets jammed up from excess friction, leading to poor quality finished products no matter what kind of project they're working on.

Proper Storage to Prevent Rust

Getting proper storage right makes all the difference when it comes to keeping aviation snips free from rust and corrosion problems. These cutting tools need to live somewhere dry and clean, away from damp spots or places where chemicals might get on them. A good option for most workshops is storing them inside plastic toolboxes that contain some kind of rust inhibitor lining. When humidity levels rise too high or there's constant exposure to water vapor, metal starts breaking down faster than normal. This means the snips won't cut as well over time and eventually just break apart completely. Most experienced mechanics know this already, which is why they always keep their aviation snips properly protected between jobs.

How to Choose the Right Aviation Snips

Assessing Project Requirements (HVAC, Roofing, etc.)

Picking the right tin snips for any job really depends on what exactly needs to get done. Take HVAC work for example, where technicians spend a lot of time cutting through ductwork. These jobs usually call for snips that have those special curved blades. Roofing contractors tell a different story though. They tend to prefer aviation snips with longer cutting edges when dealing with straight runs of metal. The material matters too. Sheet metal versus aluminum makes a big difference, especially when considering thickness. Thicker sheets definitely need stronger blades that can handle the resistance without getting damaged. Lighter gauge metals don't require such heavy duty tools. Industry specifics play their part as well. Many HVAC professionals swear by the Malco Max2000 Double Cut Aviation Snips for their versatility. Roofers commonly reach for something like the Midwest Power Cutter Offset Long Cut Aviation Snip because it handles those long straight cuts so much better.

Balancing Budget and Professional-Grade Quality

Deciding whether to go for cheap tools or spend extra on good quality stuff is something every DIY person faces at some point. The budget versions, such as those Craftsman aviation snips many folks grab when they start out, work fine for now and then jobs around the house. But serious hobbyists know that spending a bit more initially actually pays off over time because these nicer snips don't break down so easily and cut materials much cleaner without all that annoying resistance. People who have used both types report that their expensive pair lasted years while cheaper ones needed replacing after just a few big projects. Still worth thinking about how often someone will really be using these tools before making a choice though. A weekend warrior probably doesn't need top shelf equipment but anyone doing regular cutting should definitely invest in something that lasts.

Brand Reputation

When buying tools like aviation snips, brand reputation is a key factor. Trusted brands are known to deliver better quality, performance, and durability, giving buyers confidence in long-term value.

Why Choose a Trusted Brand?

⢠Consistent product quality

⢠Reliable cutting performance

⢠Stronger after-sales support and warranties

â TIANXIN Aviation Snips: Trusted by Professionals

TIANXIN is a reputable manufacturer known for producing high-performance aviation snips that meet global standards. Backed by strict quality control and positive customer feedback, TIANXIN snips offer durability, precision, and value you can trust. Many professionals rely on TIANXIN for tools that deliver results and last longer.

Testing Ergonomics Before Purchase

Before buying aviation snips, it makes sense to check out their ergonomics so they won't cause discomfort or hand strain after hours of work. Tools that fit right in the hand really make a difference, offering better control while cutting down on those annoying aches and pains. When looking at ergonomics, pay attention to how the handles feel when gripped, whether the snips feel balanced in the hand, and how smoothly the blades open and close. Good quality models usually have non-slip grips and padded handles which are lifesavers for anyone who needs to cut metal all day long without their hands getting sore.

Frequently Asked Questions

What materials can aviation snips effectively cut?

Aviation snips are versatile tools typically used for cutting metal sheets, including tin, aluminum, and even lightweight steel. Their gauge compatibility indicates the thickness of materials they can handle efficiently.

How can I maintain my aviation snips for longevity?

Regular maintenance includes cleaning metal shavings, lubricating pivot points, and storing them properly to prevent rust. Additionally, inspect the blades for wear and replace them when necessary.

Why is ergonomic design important in aviation snips?

An ergonomic design reduces hand fatigue and increases efficiency during extended use. Features like rubber grips and contoured shapes enhance comfort and handling.

What are compound leverage mechanisms in aviation snips?

Compound leverage mechanisms amplify the user's applied force, making it easier to cut through metal with less effort, improving efficiency and reducing fatigue during use.